Reliability

When the weather gets warm and the sun starts shining, few things are as anticipated as a day on the water. At Malibu Boats™, we get that and we do everything possible to make sure engine issues don’t cut into your family time. Nowhere is this more apparent than in our new Malibu Monsoon M5Di™ and Malibu Monsoon M6Di™ direct injection engines.

Engines are complex to say the least, so at Malibu we do as much as we can to simplify them. To that end, we acquired a 70,000-square-foot building right next door to our boat plant in Tennessee and outfitted it to make the most reliable engines the towboat world has ever seen. Everything on an engine needs to be precise, so we started by outfitting our new engine manufacturing plant with smart tools. Smart tools allow the technicians to see the torque specs for each fastener on a screen, and the system won’t move on until ideal torque is achieved by the proper tool with the proper fastener. The system completely removes human error from the equation.

Engines Built for Reliability

Watch and see why Malibu Monsoon Engines were designed to make sure engine issues never cut into your time on the water.

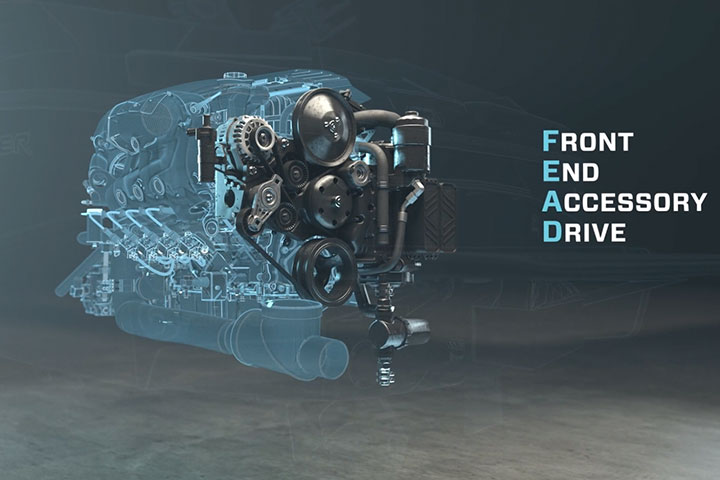

WatchIn addition, Malibu worked with key partners to fabricate parts from scratch for the M5Di and M6Di. These parts were critical in the transition from an automotive block to a fully integrated marine engine. The process is called marinizing, and it makes or breaks your engine’s reliability. Malibu engineers and partners spent thousands of hours designing, 3D-printing and testing over 200 custom parts to make what would become the backbone of the new Monsoon engines’ reliability: The Front-End Accessory Drive, or FeAD. Malibu’s exclusive FeAD eliminates the automotive water pump and relocates many important components like the alternator, Glycol circulation pump, thermostat housing and transmission cooler up higher in the engine, where they are easily serviced. Several failure points were eliminated by the FeAD alone. Furthermore, FeAD’s innovation extends to eliminating raw water circulation throughout the engine, substituting Glycol for cooling. Glycol is an antifreeze compound that cools the engine and its components far more efficiently than raw water. In Malibu’s new Monsoon line, the exhaust is the only component being touched by raw water, which causes corrosion problems in more sensitive engine parts. This is accomplished by moving critical components like the engine block, transmission cooler and oil cooler into the Glycol circuit, where they can be cooled without being exposed to a single drop of raw water.

The other key point is that raw water almost always contains seaweed of some kind, which can get caught in the oil coolers and overheat the engine. Every Malibu engine comes standard with a strainer and by eliminating the oil coolers from the raw water flow, there is no chance that seaweed will ruin your day. Any of these things can ruin your day on the water, unless your engine has Malibu’s exclusive FeAD system.

Malibu has poured over 5,000 combined hours of dyno and in-vessel testing to ensure your new M5Di or M6Di is the most reliable, hassle-free engine on the water today. Reliability is one of the things Malibu and Axis owners take for granted, and we aim to keep it that way. To schedule your day on the water, contact your local dealer today.

To find out more about the benefits of Malibu’s new line of Monsoon direct injection engines, check out our other articles on performance, emissions and noise reduction.

Malibu Monsoon Engines

Want to know more? Click below to learn more information on the Malibu Monsoon M5Di and M6Di.

Learn More